Unique Advantages of UV DTF Printing

UV DTF printing merges UV and direct-to-film techniques. It delivers versatile, efficient solutions for businesses and creators. This innovative method produces high-quality, durable prints. It works on diverse surfaces, transforming the printing industry. Here, we explore why UV DTF is revolutionary.

Versatility Across Substrates

UV DTF adheres to materials like glass, metal, wood, ceramics, and plastics. Traditional methods often require specific substrates. However, UV DTF uses a special film for transfers. This allows printing on nearly any surface. It’s perfect for customizing phone cases, mugs, and industrial parts. Businesses can create unique products effortlessly. Also, it supports irregular shapes, unlike traditional printing. This flexibility opens new creative possibilities.

For example, a small business can print logos on glassware. Manufacturers can decorate metal components with precision. UV DTF’s adaptability suits both small and large projects. It eliminates the need for costly surface treatments. This makes it a game-changer for customization.

Exceptional Durability

UV DTF prints cure instantly with ultraviolet light. This creates a strong ink-to-film bond. Prints resist scratches, water, and UV exposure. They are ideal for outdoor use, such as signage. Also, they withstand frequent handling, like on phone cases. This ensures long-lasting vibrancy and quality.

Unlike traditional prints, UV DTF resists fading. However, durability depends on proper application. The cured ink forms a protective layer. This makes it suitable for harsh environments. For instance, outdoor furniture with UV DTF prints maintains its look. Businesses benefit from reliable, durable products.

Vivid and High-Quality Prints

UV-curable inks produce vibrant colors and sharp details. They deliver high-resolution images with excellent color accuracy. UV DTF suits intricate designs, logos, and graphics. Also, white ink as a base layer boosts opacity. This ensures colors pop on dark or transparent surfaces.

For example, a retailer can print detailed artwork on clear acrylic. The results are crisp and eye-catching. However, precision in printing is key. UV DTF’s ability to handle gradients and textures is unmatched. It elevates branding and creative projects significantly.

Eco-Friendly Process

UV DTF is environmentally friendly compared to traditional methods. The UV-curing process emits minimal volatile organic compounds (VOCs). Inks lack harmful solvents, reducing environmental impact. Also, precise application minimizes waste. This uses less ink and materials.

Traditional printing often generates excess waste. However, UV DTF’s efficiency benefits eco-conscious businesses. For instance, small print shops can reduce their footprint. The process supports sustainable production without sacrificing quality. It’s a win for both businesses and the planet.

Cost-Effective for Small Batches

UV DTF is ideal for small-batch production. Traditional screen printing requires costly setup for each design. However, UV DTF’s digital process eliminates screens or plates. This reduces upfront costs significantly. Also, it supports one-off customizations affordably.

Small businesses can offer personalized gifts without high expenses. For example, a shop can print custom mugs cost-effectively. UV DTF makes short runs profitable. It empowers entrepreneurs to compete with larger firms. This affordability drives innovation and market growth.

Fast Turnaround Times

UV DTF printing is streamlined with instant curing. It requires minimal setup, speeding up production. Businesses can meet tight deadlines easily. Also, on-demand printing suits time-sensitive projects. This is faster than traditional methods.

For instance, event planners can produce branded merchandise quickly. However, efficiency depends on proper equipment. UV DTF’s speed enhances customer satisfaction. It allows businesses to fulfill orders promptly. This makes it a top choice for urgent needs.

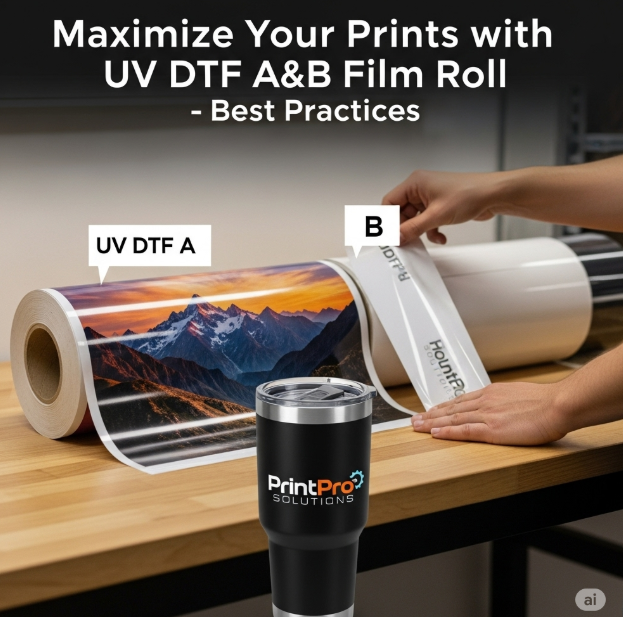

Ease of Application

UV DTF uses a simple transfer process. Designs print onto a film, then transfer with heat and pressure. This requires minimal training and equipment. Also, it’s accessible for small businesses. Entrepreneurs can adopt UV DTF easily.

Unlike complex traditional methods, UV DTF is user-friendly. However, proper technique ensures optimal results. For example, a hobbyist can create custom decor effortlessly. This simplicity broadens its appeal across industries. It supports both beginners and professionals.

Customization and Flexibility

UV DTF excels in creating unique, tailored products. It’s perfect for personalized gifts and branded merchandise. Also, it handles complex designs with gradients and textures. This enhances creative expression significantly. Businesses can offer bespoke items confidently.

For instance, artists can print detailed designs on ceramics. However, creativity requires precise execution. UV DTF’s flexibility suits promotional items and niche markets. It empowers brands to stand out. This versatility drives customer engagement and loyalty.

Real-World Applications

UV DTF is transforming various industries. Retailers use it for custom apparel and accessories. Manufacturers apply it to industrial parts. Also, event organizers create branded giveaways efficiently. The technology supports both small and large-scale projects.

For example, a wedding planner can print custom glassware. However, quality control is essential for consistency. UV DTF’s adaptability suits diverse needs. It’s used in signage, home decor, and electronics. This broadens its impact across markets.

Future Potential

UV DTF’s technology continues to evolve rapidly. Innovations in inks and films enhance performance. Also, automation is improving production efficiency. This promises even greater accessibility for businesses. However, staying updated with advancements is crucial.

The technology could expand into new sectors. For instance, medical equipment customization is a possibility. UV DTF’s future looks promising for creative industries. It will likely drive further innovation in printing.

Conclusion - UV DTF Printing

UV DTF printing revolutionizes the industry with versatility and durability. It produces vibrant, eco-friendly prints cost-effectively. Also, it supports fast production and easy application. Suitable for various surfaces, it’s ideal for customization. However, proper execution ensures optimal results. UV DTF Printing empowers businesses to create innovative, high-quality products efficiently.