Unlocking the Potential of DTF Film: A Comprehensive Guide to Custom Printing

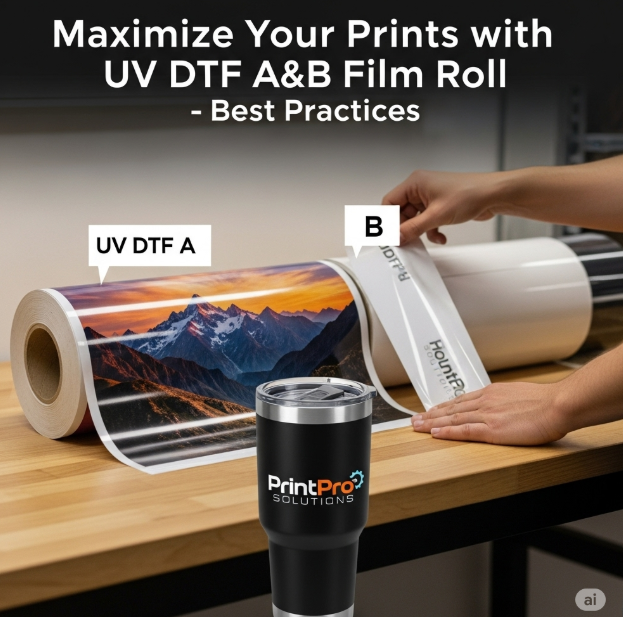

In the world of custom printing, the technology behind Direct-to-Film (DTF) printing has revolutionized the industry. DTF printing allows for vibrant, durable, and high-quality prints on a variety of materials. One of the key components to making this process work seamlessly is DTF film. This specialized film acts as the transfer medium for the designs, enabling printers to print intricate, colorful designs that can be easily applied to various substrates. In this guide, we’ll explore the potential of Direct-to-Film, how it works, and how you can harness its power to unlock new possibilities for custom printing.

What is Direct-to-Film?

Direct-to-Film is a specially coated transfer film used in Direct-to-Film printing. It’s designed to receive prints directly from a DTF printer, which uses heat to transfer the ink onto the film. The film is then heated again to transfer the design onto a fabric or other material. DTF printing is widely used for creating custom apparel, accessories, and promotional products due to its high quality and versatility.

DTF film has a smooth, matte finish and is generally available in both roll and sheet formats, offering flexibility in print size and design. It works with both white and colored fabrics, making it a favorite among custom print shops and small businesses.

How Does Direct-to-Film Work?

The process of printing with DTF film is relatively simple but requires specific steps to ensure optimal results:

-

Printing the Design:

The design is first printed onto the DTF film using a specialized DTF printer. This printer uses water-based inks, which are ideal for creating vibrant and durable prints on a variety of materials. The print process typically involves printing the image onto the matte side of the DTF film. -

Applying the Adhesive Powder:

After the design is printed, an adhesive powder is applied to the printed film. The powder sticks to the wet ink and helps create a bond between the design and the material to which it will be transferred. -

Curing the Film:

The film with the adhesive powder is then passed through a curing oven to melt and set the powder onto the film. This curing step ensures that the design will adhere to the material when pressed. -

Transferring the Design:

Finally, the film with the printed design is placed onto the material (such as a t-shirt, hoodie, or accessory), and a heat press is used to apply heat and pressure. The heat melts the adhesive, transferring the design from the film to the fabric. The result is a high-quality, durable print that is soft to the touch and resistant to fading.

Benefits of DTF Film in Custom Printing

DTF film has several advantages that make it an excellent choice for custom printing. Here are some of the key benefits:

-

Versatility:

One of the most significant advantages of DTF film is its ability to print on a wide range of materials. This includes cotton, polyester, nylon, leather, and even non-fabric items such as wood or canvas. DTF printing opens up new possibilities for custom products beyond just clothing, allowing you to create personalized items for any occasion or market. -

Durability:

Prints made with DTF film are highly durable. The designs resist fading, cracking, or peeling, even after multiple washes. This makes DTF an ideal choice for custom apparel that will be worn regularly or for promotional items that need to withstand wear and tear. -

High-Quality Prints:

DTF film allows for vibrant, full-color prints with sharp details. Whether you're printing intricate designs, logos, or photographs, the results are consistently high quality. The film ensures smooth transitions in color and fine details, providing a professional finish every time. -

Cost-Effective:

DTF printing is a cost-effective solution for custom printing, especially for small runs. Unlike traditional screen printing, which requires expensive setup costs and large quantities, DTF printing allows you to print just a few pieces at a time without incurring significant overhead. This makes it a great option for small businesses or custom shops that want to offer personalized products at affordable prices. -

No Need for Cutting or Weeding:

DTF printing doesn't require cutting or weeding designs like traditional vinyl printing. This eliminates the time-consuming process of manually cutting around designs and reduces the risk of mistakes, allowing for faster production times. -

Soft to the Touch:

Unlike other transfer methods, DTF prints have a soft, flexible feel on the fabric. The design won't feel stiff or heavy, allowing the material to retain its natural softness and breathability.

Applications in Custom Printing

Custom printing offers endless possibilities, and one of the most versatile tools available is a specialized film used in transfer printing. This film allows for the creation of a wide variety of personalized products. Here are some of the most popular applications:

Custom Apparel:

This film is commonly used for printing custom designs on t-shirts, hoodies, hats, and other clothing items. Whether you're making shirts for a family reunion, launching your own clothing line, or creating branded merchandise, the results are vibrant and durable.

Promotional Products:

Creating customized promotional items like bags, caps, mugs, and other accessories is made easy with this printing method. Adding logos, slogans, or unique designs helps businesses connect with their customers and promote their brands effectively.

Personalized Gifts:

Custom gifts such as pillows, blankets, tote bags, and phone cases are always in demand. This film enables you to craft high-quality, unique gifts that are perfect for special occasions, making them great keepsakes for recipients.

Home Décor:

This film isn’t limited to just clothing—it can also be used to create personalized home décor items like pillowcases, tablecloths, and wall art. It's an excellent choice for offering customized home items that add a personal touch to any living space.

Custom Accessories:

From leather bags to wallets and shoes, this printing method allows for the creation of intricate, detailed designs on various materials. Personalized accessories are increasingly popular, and this film helps bring those designs to life.

Tips for Getting the Best Results

To ensure high-quality, long-lasting prints, follow these tips for optimal results:

-

Use High-Quality Film:

Not all transfer films are equal. High-quality films yield the best colors and durability, so investing in premium options ensures the best possible outcomes. -

Proper Curing:

Curing is a critical step in the process. Be sure to properly set the adhesive powder to ensure it bonds effectively with the fabric. Failure to do so may result in peeling or fading. -

Correct Temperature and Pressure Settings:

Different materials require different settings on the heat press. Always refer to the recommended guidelines for temperature and pressure to achieve the best transfer. -

Avoid Overloading the Printer:

Precision is essential when printing, so avoid overloading your printer with too many projects at once. This helps ensure better print quality and prevents issues like ink smearing or misalignment.

Final Thoughts

The versatility and effectiveness of this specialized film have revolutionized custom printing. Whether you're creating personalized apparel, unique promotional products, or one-of-a-kind gifts, the printing process delivers high-quality and durable results. Thanks to its cost-effectiveness, ease of use, and versatile applications, it is a perfect choice for businesses, hobbyists, and anyone looking to create customized items with professional results. Embrace this technology, and take your custom printing projects to new heights!