DTF Printing

Direct-to-Film (DTF) printing is a versatile and popular method for creating vibrant, high-quality designs on various fabrics. However, optimizing your DTF printing workflow is key to increasing efficiency, reducing costs, and meeting tight deadlines. Below, we’ll explore practical tips and strategies to streamline your DTF printing process without compromising quality.

1. Optimize Your Design Process

Creating efficient designs can save significant time in the DTF printing workflow.

-

Use High-Quality Design Software: Invest in reliable graphic design software like Adobe Photoshop, Illustrator–

-

Simplify Designs When Possible: Complex designs with intricate details can slow down the printing process. Simplify designs where appropriate to reduce file sizes and printing times, while maintaining visual appeal.

-

Batch Similar Designs: Group designs with similar colors or sizes to minimize setup time. This reduces the need for frequent changes in ink or film settings, speeding up the overall process.

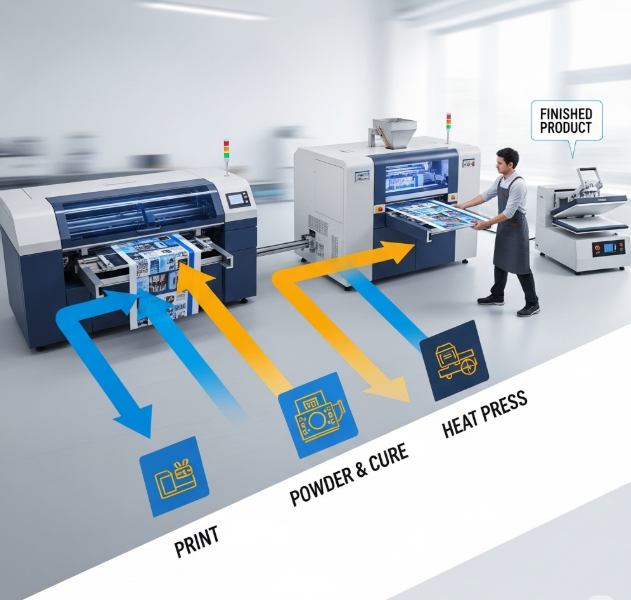

2. Invest in the Right Equipment

Your choice of equipment plays a critical role in the speed and efficiency of your DTF printing workflow.

-

Choose a High-Speed DTF Printer: Not all DTF printers are created equal. Look for models with faster print heads or higher resolution capabilities to reduce printing time. Research brands like Epson, Mimaki, or Roland for reliable options.

-

Upgrade Your Heat Press: A high-quality heat press with consistent temperature and pressure settings can significantly reduce transfer times. Dual-station heat presses allow you to prep one item while another is being pressed, doubling your output.

-

Automate Where Possible: Consider automated shakers and curing ovens to streamline the powder application and curing process. Automation reduces manual labor and ensures consistent results.

3. Streamline Pre-Press Preparation

The pre-press stage is where many bottlenecks occur. Optimizing this phase can save valuable time.

-

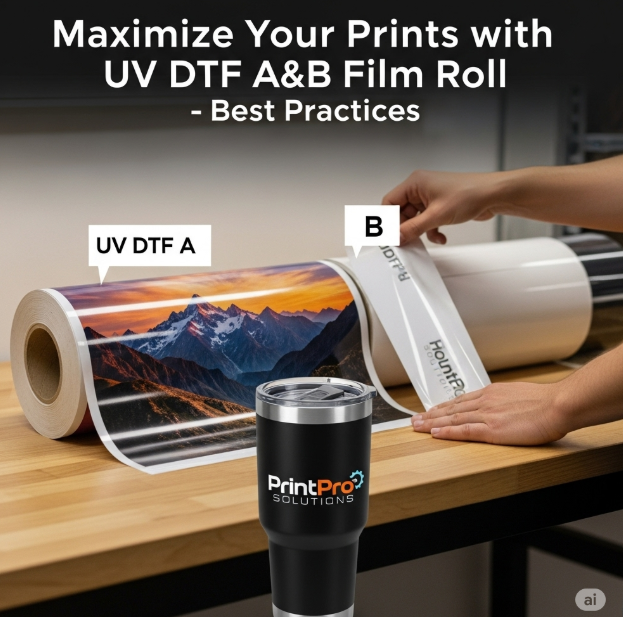

Pre-Cut Films: Pre-cut your DTF films to standard sizes to reduce setup time. This is especially helpful for high-volume orders.

-

Calibrate Your Printer Regularly: Regular calibration ensures accurate color reproduction and minimizes reprints due to errors. Schedule maintenance checks to avoid unexpected downtime.

-

Use Pre-Treated Fabrics: Some fabrics require pre-treatment to ensure proper ink adhesion. Using pre-treated fabrics can eliminate this step, saving time in the workflow.

4. Master the Printing Process

Efficient printing techniques can significantly boost your workflow.

-

Optimize RIP Software Settings: RIP (Raster Image Processor) software controls how your printer processes images. Adjust settings like resolution, ink density, and color profiles to balance speed and quality. Popular RIP software options include CADlink and Onyx.

-

Print in Batches: Printing multiple designs in a single run reduces setup and cleaning time. Arrange designs on the film to maximize space and minimize waste.

-

Monitor Ink Levels: Running out of ink mid-print can disrupt your workflow. Use printers with ink level monitoring or keep spare ink cartridges on hand to avoid interruptions.

5. Perfect the Transfer Process

The transfer stage is where your design comes to life. Streamlining this step ensures faster turnaround times.

-

Standardize Transfer Settings: Create a cheat sheet for heat press settings (temperature, pressure, and time) for different fabrics. This reduces trial-and-error and ensures consistent results.

-

Use a Conveyor Dryer for Large Orders: For high-volume production, a conveyor dryer can cure transfers faster than a traditional heat press, keeping your workflow moving.

-

Train Your Team: Ensure all team members are trained on the transfer process to avoid mistakes and maintain speed. Cross-training employees can also help cover multiple roles during peak times.

6. Implement Quality Control Measures

Quality control prevents costly reprints and delays.

-

Inspect Films Before Transfer: Check printed films for defects like smudging or misalignment before transferring them to fabric. This saves time and materials.

-

Test on Scrap Fabric: Before running a large batch, test your design on scrap fabric to ensure the settings are correct. This reduces the risk of errors on the final product.

-

Keep a Clean Workspace: Dust and debris can ruin prints or transfers. Maintain a clean workspace to avoid contamination and ensure consistent quality.

7. Leverage Software for Workflow Management

Using software to manage your workflow can help you stay organized and efficient.

-

Use Print Management Software: Tools like Printful or ShopWorks can help track orders, manage inventory, and schedule production, reducing manual oversight.

-

Automate Order Processing: If you’re running an online store, integrate your DTF printing setup with e-commerce platforms like Shopify or WooCommerce to automate order imports and status updates.

-

Track Performance Metrics: Monitor key metrics like print time, error rates, and material usage to identify bottlenecks and areas for improvement.

8. Maintain Your Equipment

Regular maintenance prevents unexpected downtime and keeps your workflow running smoothly.

-

Clean Print Heads Regularly: Clogged print heads can slow down printing or cause defects. Follow the manufacturer’s cleaning schedule to keep your printer in top condition.

-

Check Film and Ink Quality: Low-quality films or inks can lead to poor adhesion or color issues, slowing down production. Source materials from reputable suppliers.

-

Schedule Routine Maintenance: Set a maintenance schedule for your printer, heat press, and other equipment to avoid breakdowns during peak production times.

9. Train and Empower Your Team

A well-trained team is essential for a fast and efficient workflow.

-

Provide Ongoing Training: Keep your team updated on the latest DTF printing techniques and equipment. Regular training sessions can improve speed and reduce errors.

-

Delegate Tasks Effectively: Assign specific roles (e.g., design, printing, transfer) to team members based on their strengths to optimize the workflow.

-

Encourage Feedback: Your team may have insights into bottlenecks or inefficiencies. Encourage open communication to identify and address issues quickly.

10. Plan for Scalability

As your business grows, your workflow needs to adapt to handle increased demand.

-

Invest in Scalable Systems: Choose equipment and software that can handle higher volumes as your business expands.

-

Outsource When Necessary: For overflow orders, consider partnering with a reliable DTF printing service to avoid overloading your in-house setup.

-

Track Industry Trends: Stay updated on new DTF technologies, such as faster printers or eco-friendly inks, to keep your workflow competitive.

Conclusion

Speeding up your DTF printing workflow requires a combination of smart planning, the right equipment, and efficient processes. By optimizing each stage—design, pre-press, printing, transfer, and quality control—you can boost productivity, reduce costs, and deliver high-quality products faster. Regularly evaluate your workflow, invest in training, and embrace automation to stay ahead in the competitive world of DTF printing.