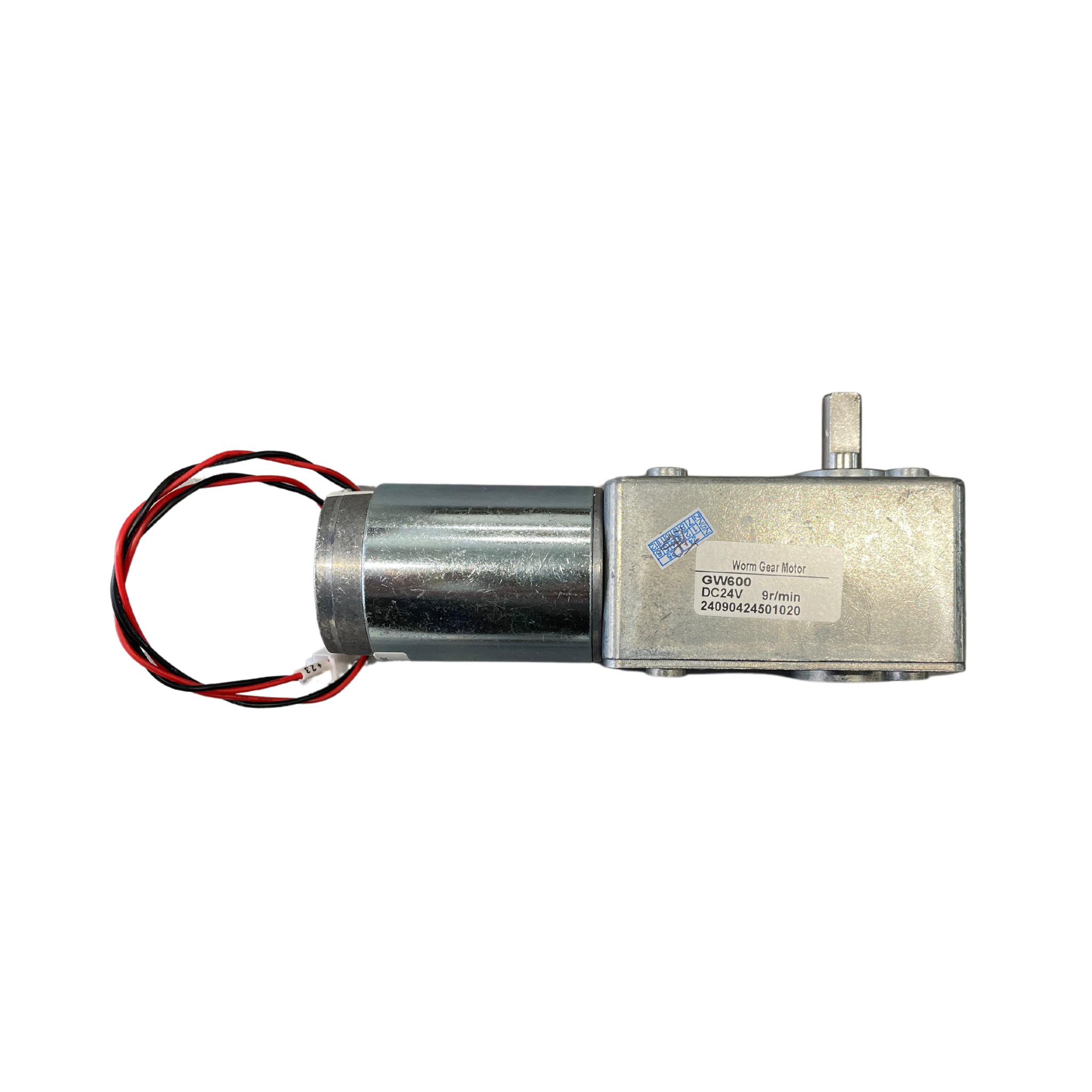

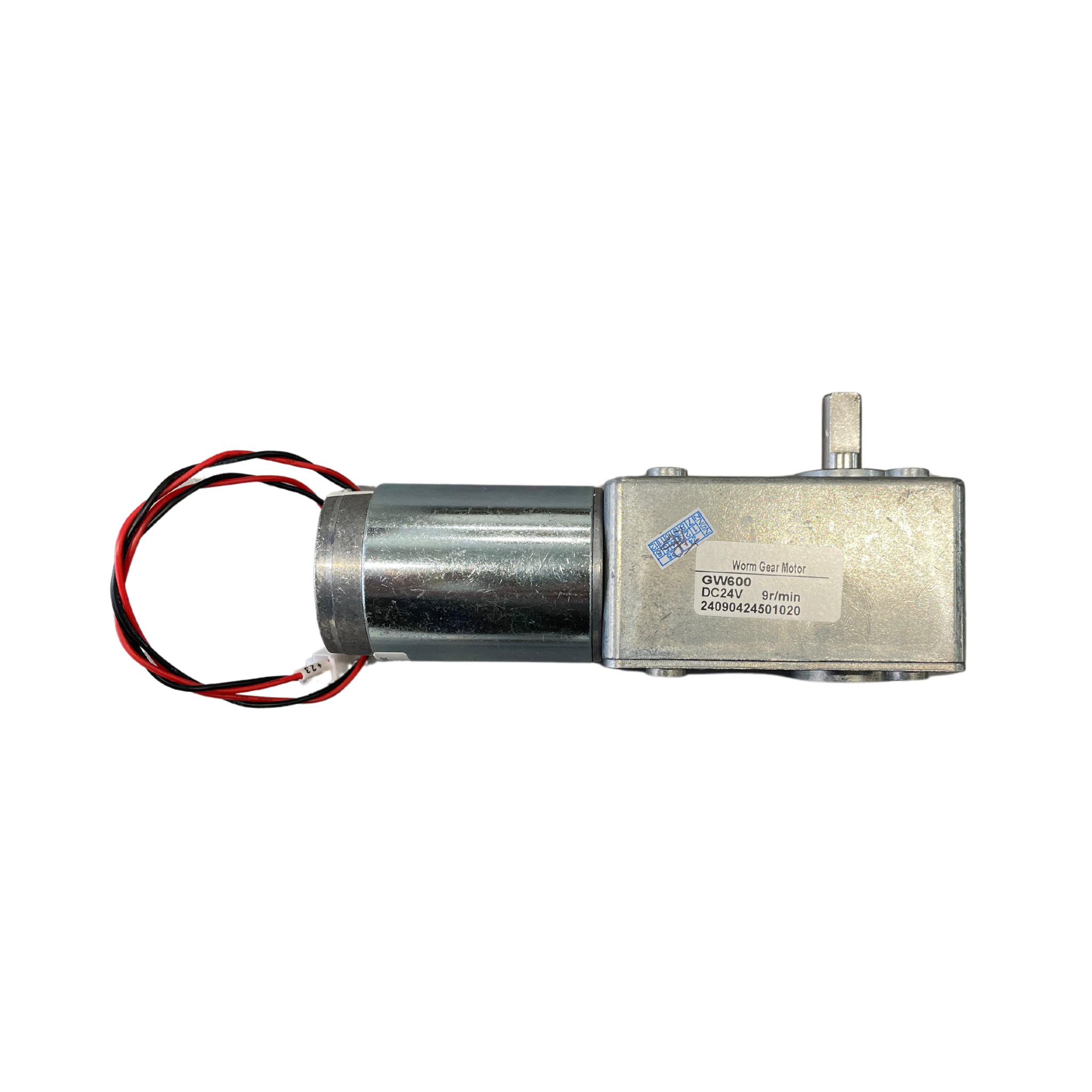

Powder Disperse Motor

Ask a question

Description

Powder Disperse Motor

The Powder Disperse Motor is an essential component in modern powder coating and printing systems. Designed to ensure uniform dispersion of powder materials, it allows for consistent application and superior surface finish. By maintaining a steady flow and controlled distribution of powders, this motor helps achieve high-quality results while reducing waste and improving overall efficiency. Its robust construction and precise engineering make it a reliable choice for both industrial and commercial applications.

Key Features

The Powder Disperse Motor is built with durable materials that withstand continuous operation in demanding environments. High-quality bearings and a sturdy housing ensure long-term performance and reduce maintenance needs. Its compact design allows for easy integration into existing powder handling systems without requiring significant modifications. The motor is engineered to operate quietly and efficiently, contributing to a safer and more comfortable working environment.

Precision engineering ensures consistent rotation speed and torque, which are critical for uniform powder dispersion. The motor’s controlled operation prevents clumping or uneven application, supporting high-quality surface finishes. Its design is compatible with a range of powders and materials, making it versatile for various industrial processes.

Efficient Powder Dispersion

Effective powder dispersion is crucial for achieving uniform coating and reducing defects. The Powder Disperse Motor provides consistent agitation, keeping particles in motion and evenly distributed. This ensures that powders do not settle or form clumps, which can lead to uneven surfaces or material waste. Industries such as textiles, plastics, and DTF printing benefit from this precise control, improving both product quality and production efficiency.

The motor’s stable performance allows operators to maintain optimal processing conditions. Consistent dispersion reduces rework and minimizes downtime caused by uneven coating or material blockages. By supporting smooth powder flow, the motor ensures reliable operation across different batches and materials.

Durability and Reliability

Durability is a key feature of the Powder Disperse Motor. It is designed to withstand continuous operation under heavy loads and harsh industrial conditions. The motor housing is constructed from corrosion-resistant materials, protecting internal components from dust, moisture, and chemical exposure. High-quality bearings and shafts reduce wear and extend the operational lifespan.

Regular maintenance is straightforward, with accessible components for inspection and servicing. The motor’s robust construction minimizes the risk of breakdowns, ensuring consistent production and reducing unexpected downtime. This reliability is essential for businesses that rely on continuous powder processing and high-quality output.

Versatile Applications

The Powder Disperse Motor is suitable for a wide range of applications. In the textile industry, it ensures uniform coating of powders on fabrics, improving adhesion and surface quality. In the plastics and coatings sectors, it supports consistent distribution of pigments, powders, or additives, enhancing product consistency and appearance. In DTF printing and other specialized printing applications, it keeps powders evenly suspended, ensuring sharp, vibrant results on printed materials.

Its versatility also makes it compatible with various powder materials, including metallic powders, pigments, adhesives, and chemical additives. This adaptability allows manufacturers to use the same motor across multiple processes, simplifying equipment needs and reducing operational costs.

Easy Installation and Operation

The Powder Disperse Motor is designed for straightforward installation. Clear instructions guide operators through mounting and electrical connections, reducing setup time. Its compact footprint allows it to fit easily into existing machinery without major modifications. Once installed, the motor operates smoothly and efficiently, with simple controls to adjust speed and torque according to the specific powder handling requirements.

The motor is suitable for both manual and automated systems. Its consistent performance ensures reliable results, even in fully automated production lines. The simple design minimizes potential issues, making it accessible for operators with varying levels of technical experience.

Energy Efficiency

Energy efficiency is an important consideration in modern industrial equipment. The is optimized to consume minimal power while maintaining consistent performance. Its efficient design reduces energy costs, lowers environmental impact, and contributes to sustainable production practices. By providing precise control over rotation speed and torque, the motor achieves effective powder dispersion without wasting energy or material.

Maintenance and Longevity

Maintaining the is simple and cost-effective. Components are accessible for inspection, cleaning, and replacement if necessary. Routine lubrication of bearings and checking of connections helps extend the motor’s operational life. The motor’s durable construction reduces wear, ensuring stable performance over long periods of continuous operation. By following basic maintenance practices, operators can maximize reliability and minimize downtime.

Benefits

Using the provides numerous advantages. It ensures uniform powder dispersion, improving coating quality and surface finish. Its durable design and reliable operation reduce maintenance needs and prevent costly production interruptions. The motor supports energy-efficient operation, contributing to lower operating costs and sustainable processes. Its versatility allows use across various materials and industries, enhancing overall production efficiency.

Safety and Compliance

Safety is a critical consideration when operating industrial motors. Includes protective housings and secure mounting points to prevent accidental contact with moving parts. Electrical components are insulated to reduce the risk of shocks or short circuits. The motor is designed to meet industry standards for safety and performance, ensuring compliance with regulatory requirements and safe operation for personnel.

Conclusion

The is an essential component for achieving efficient and reliable powder handling. Its precise engineering, durable construction, and energy-efficient operation ensure consistent results across multiple applications. By providing uniform powder dispersion, it enhances product quality, reduces waste, and improves operational efficiency.

Suitable for textiles, plastics, coatings, DTF printing, and other industrial processes, the motor offers versatility and reliability. Easy installation, minimal maintenance, and smooth operation make it a practical choice for both small-scale and large-scale production. Investing in a high-quality Powder Disperse Motor ensures consistent performance, improved product quality, and long-term efficiency in any powder handling system.

Shipping

At Fast DTF Supply, we use trusted carriers to ensure your orders are delivered safely and promptly, offering shipping methods such as ground or air.

Orders placed before 2 Eastern Time (ET) are shipped the same business day to get your products to you as quickly as possible. Orders received after this time will be shipped the next business day.

Shipping costs will be calculated at checkout based on the location provided, the shipping option selected, and the total weight of the purchase.

Currently, Fast DTF Supply does not offer international shipping and ships exclusively within the United States to focus on delivering the best possible service to our domestic customers.

Fast DTF Supply is not responsible for any delays that occur after the package is handed over to the shipping company.

While we strive to meet all delivery times, there may be occasions due to unforeseen circumstances where deliveries could be delayed. We appreciate your understanding and patience in these instances.

For more details, check out our Shipping Policy.

Pickup available at Fast DTF Supply Usually ready in 24 hours

Pickup available

-

Fast DTF Supply

Pickup available, usually ready in 24 hours

1 Apollo Drive

Check in google map

Unit D

Whippany NJ 07981

United States

Guarantee Safe Checkout